In the world of chemistry, the shape of a vessel is rarely an aesthetic choice—it is a physics equation made of borosilicate glass.

A recent debate in the chemistry community regarding “2-neck vs. 3-neck flasks” highlighted a deeper understanding of laboratory safety. Beyond the convenience of extra ports, the discussion revealed critical insights into pressure dynamics and vacuum safety.

Here is the science behind why your flask looks the way it does.

1. The Arch vs. The Drum: Vacuum Physics

Why are reaction flasks round?

Many beginners prefer Flat Bottom Flasks for convenience. However, seasoned chemists know that applying a vacuum to a flat surface is a recipe for disaster.

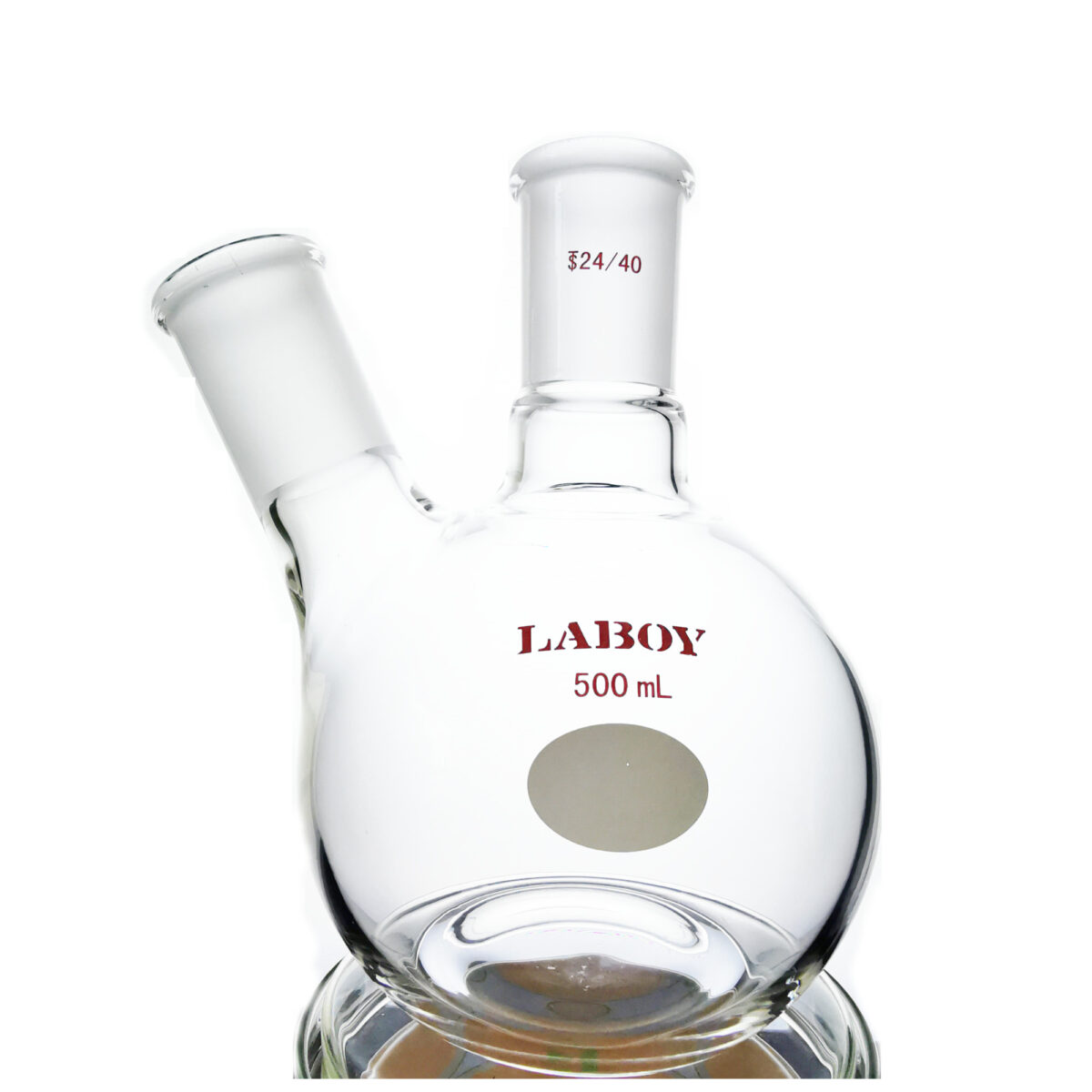

- Round Bottom Flasks (RBF): These utilize the principle of the Arch. When a vacuum is pulled inside, atmospheric pressure pushes inward. A sphere distributes this compressive stress evenly across the entire surface. It is nature’s strongest shape.

- Flat Bottom Flasks: These act like a Drum Skin. Atmospheric pressure pushes on the flat center, creating massive bending stress. Glass is strong in compression but weak in tension/bending. A flat bottom under vacuum is prone to catastrophic implosion.

The Takeaway: Flat bottoms are for storage. Round bottoms are for reactions. Never confuse the two.

2. The Probability of Leaks: Joint Theory

When selecting between a 2-neck and a 3-neck flask, one must consider the “Leak Probability.”

In engineering, every connection point is a potential point of failure. In chemistry, every Ground Glass Joint (Standard Taper) is a potential vacuum leak.

- 3-Neck Flasks: Ideal for complex organic synthesis where you need to reflux, monitor temperature (thermowell), and add reagents simultaneously.

- 2-Neck (or Single Neck) Flasks: Preferred for High Vacuum work.

If you are running a Schlenk line or trying to achieve a deep vacuum, a 3-neck flask requires three perfect seals. A 2-neck flask reduces your risk margin by 33%. As one forum member noted, “More necks = Better versatility, but fewer necks = Better vacuum.”

3. Practical Advice for the Modern Chemist

Based on the consensus of laboratory safety experts, here are the rules of thumb for glassware selection:

- Don’t Fear the Round Bottom: Use a cork ring or a weighted base. Never sacrifice the structural integrity of an RBF just for the convenience of a flat bottom.

- Plan Your Ports: If you are buying a general-purpose flask (e.g., 2000ml), the 3-neck RBF is usually the standard. You can always stopper a joint, but using “Claisen Adapters” to add necks to a 2-neck flask adds height, instability, and breakage risk.

- Check Your Mantle: Note that 3-neck flasks can sometimes be difficult to fit into standard heating mantles due to the angle of the side necks. Ensure your heating equipment is compatible with your glassware.

Summary

Chemistry is not just about mixing substances; it is about managing the physical environment in which those substances interact. Choosing the right flask—round vs. flat, 2-neck vs. 3-neck—is the first step in a safe and successful experiment. Unsure which configuration fits your specific needs? Read our detailed guide: 2-Neck vs. 3-Neck Boiling Flasks: Which Should You Buy for Your Lab?