Have you ever had that moment of quiet despair in the lab?

Your reaction is ready, you reach for a new addition funnel, try to fit it onto your flask, and… it doesn’t fit. Or worse, it fits, but wobbles just enough to make you nervous.

The box says “24 mm standard joint”, so why is one connector long and the other short? Why do some standard taper joints seal beautifully while others always seem to leak?

Glassware is our hardware, yet clear explanations of these joints are strangely rare in textbooks. This lack of clarity leads to real frustration at the bench—especially when you are trying to figure out the critical difference between a 24/40 and a 24/29 joint before a reaction starts.

This guide is ChemNorth’s answer to that confusion. We will map out the main joint types, decode exactly what the numbers (like 24/40) mean, explain the difference between ASTM and ISO standards, and provide a practical compatibility cheat sheet you can rely on.

Types of Laboratory Glassware Joints

Before getting lost in the numbers, it helps to see the whole map. Not all connections are created equal—each joint type has its own “personality” and typical role.

Standard Taper Joints

The Workhorse.

- Conical, ground-glass surfaces (14/20, 24/40, 29/42, NS 24/29, etc.).

- Main connection on flasks, condensers, adapters, and funnels.

- Rigid, airtight joint; this guide focuses mainly on these.

Spherical (Ball & Socket) Joints

The Flexible Gymnast.

- Rounded “ball” fits into a cup-shaped socket.

- Allows ~10–15° of angular flexibility.

- Used on rotary evaporators and long vacuum manifolds.

- Must be secured with metal pinch clamps.

Flat Flange Joints

The Heavy-Duty Solution.

- Wide, flat sealing faces clamped with an O-ring.

- Provides a large opening for reactors and vacuum vessels.

- Ideal when you need cleaning access or large stirrer shafts.

Screw Thread (GL) Joints

The Modern Modular Connector.

- External glass threads plus a plastic cap and gasket.

- Height-adjustable; no grease required.

- Common on GL45 bottles and GL14/18/25 adapters.

The Chemnorth Take: While all four types are essential, the one that causes the most headaches is undoubtedly the Standard Taper Joint.

Why? Because of the confusing numbers, conflicting international standards, and joints that claim to be the same size but turn out to be different lengths. In the next section, we’ll peel back the layers of this mystery and solve the compatibility puzzle once and for all.

Standard Taper Joint Dimensions & Sizes Explained

To understand laboratory glassware compatibility, you simply need to decode the two-number designation (written as A/B).

What do the numbers (e.g., 24/40) mean?

- The First Number (A): Represents the nominal outer diameter (OD) of the joint at its widest point, in millimeters.

- The Second Number (B): Represents the length of the ground-glass zone (the frosted area), in millimeters.

Examples:

- 24/40 Joint: Has a nominal width of 24 mm and a ground length of 40 mm.

- 14/20 Joint: Has a nominal width of 14 mm and a ground length of 20 mm.

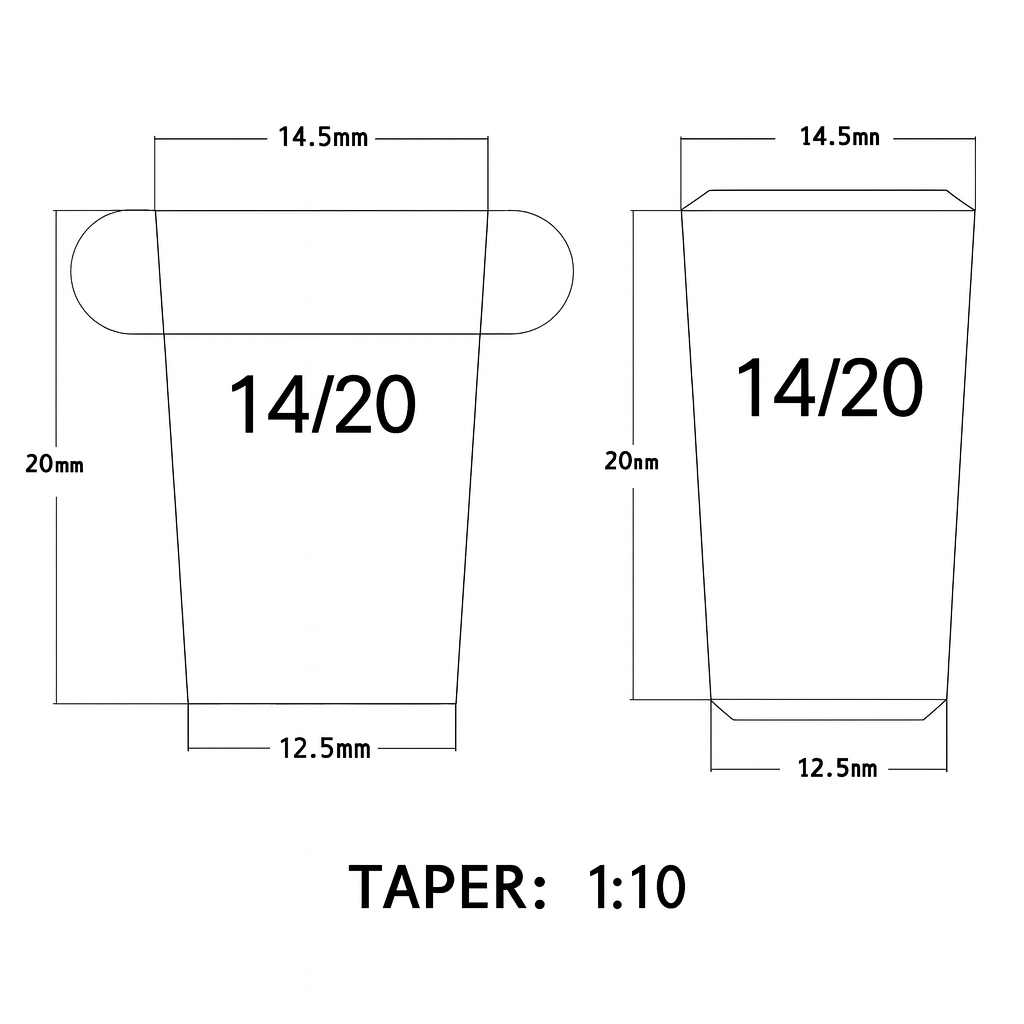

Note on Precision: The first number is a “nominal” category. For instance, in a 14/20 joint, technical diagrams often show the actual diameter is slightly larger (e.g., ~14.5 mm) to accommodate manufacturing tolerances and ensure a tight seal.

What does a 1:10 taper mean?

Regardless of the size—14/20, 24/40, or 45/50—all standard taper joints share the same 1:10 geometric slope.

So what does “1:10 taper” actually mean? It is not an angle in degrees. Instead, it means that for every 10 mm of length along the joint, the diameter changes by 1 mm. In other words, the cone is very shallow and very consistent.

For example, let’s do the math on a 14/20 joint:

- Large-end diameter: 14.5 mm

- Small-end diameter: 12.5 mm

- Difference: 2.0 mm

- Ground length: 20 mm

The diameter changes 2.0 mm over a 20 mm length, so the taper is exactly 1:10.

This matters because such a gentle, consistent slope is the secret to the joint’s reliability. It allows the joint to self-center as it is inserted, creating a tight seal without excessive force. More importantly, because the slope is fixed, joints from different manufacturers and different standards remain geometrically compatible, even when their ground lengths are not the same.

ASTM (US) vs. ISO (Europe): Same Taper, Different Lengths

Once we know the taper is fixed at 1:10, the only major variable left is the length of the ground section. This is exactly where the world divides into two camps.

The confusion often stems from one simple question: Why do US and European joints look different if they claim to be the same size?

The answer is geometry. Since the taper is identical and the nominal diameter is the same, ASTM and ISO/DIN standards are simply two different ways of slicing the same 1:10 cone.

1. US Standard (ASTM) — “Full-Length” Joints

- Typical sizes: 14/20, 24/40, 29/42

- Traits: Longer ground section with more contact area.

- Best for: Heavy, vertical glassware (tall condensers, columns, large flasks) where extra mechanical stability is valuable.

2. European Standard (ISO/DIN) — “Medium-Length” Joints

- Typical sizes: 14/23, 24/29, 29/32

- Traits: Shorter ground section that is easier to separate and less likely to “freeze” (get stuck).

- Best for: Routine work where easy disassembly and slightly lower glass cost matter more than maximum support.

ASTM vs ISO Glassware Joints: Difference Between 24/40 and 24/29

| Feature | US Standard (ASTM) | European Standard (ISO/DIN) |

|---|---|---|

| Common Name | Full-Length Joints | Medium-Length Joints |

| Typical 24 mm Joint | 24/40 | 24/29 |

| Ground Zone Length | Longer (40 mm) | Shorter (29 mm) |

| Best For | Heavy, vertical assemblies and tall condensers | Easy separation and economical glassware |

Real-World Compatibility: Can You Mix Them?

This is the most common question we hear:

“I have a European 24/29 flask and a US 24/40 condenser. Can I use them together?”

Short answer: yes, in most routine setups. Because they share the same 1:10 taper and the same nominal 24 mm diameter, a 24/40 joint and a 24/29 joint will usually seal. However, the different lengths create two distinct scenarios you need to watch out for.

Scenario A: Long Male (24/40) + Short Female (24/29)

- The fit: The long 24/40 male joint reaches further in and may stick out slightly into the flask.

- The verdict: ✅ Generally safe. The seal is good, but any exposed ground glass inside the vessel can trap residues and make cleaning more annoying.

Scenario B: Short Male (24/29) + Long Female (24/40)

- The fit: The short 24/29 male joint sits very deep inside the longer 24/40 socket, leaving part of the female ground area unused at the top.

- The verdict: ⚠️ Use with caution. Deeply seated short joints are more prone to frozen joints, especially without grease or if the setup is heated and cooled repeatedly. Always use a Keck clip to stop the joint from creeping deeper under its own weight.

Chemnorth Pro Tip: When mixing ASTM and ISO joints, ALWAYS use Keck clips. Since the lengths don’t match perfectly, the clip is essential to fix the relative position—preventing short joints from sinking too deep and long joints from wobbling.

For routine organic synthesis—reflux, simple distillation, moderate vacuum—mixing 24/29 and 24/40 is usually acceptable if you handle the glass with care and understand these caveats.

For high vacuum, long, hot runs, or heavy, tall assemblies, it is safer to commit to one standard throughout the setup and avoid mixed-length joints altogether.

The Master Cheat Sheet

This is the part you’ll want to print and tape to the lab wall.

Standard Taper Joint Sizes (Quick Reference Table)

If you just want a ground glass joint size chart to check which joint goes with which flask, this table collects the most common standard taper joint sizes and uses.

| Lab Scale | Common Diameter | US Standard (ASTM) | EU Standard (ISO) | Typical Application |

|---|---|---|---|---|

| Micro | 14 mm | 14/20 | 14/23 | < 50 mL reactions, expensive reagents |

| Standard | 24 mm | 24/40 | 24/29 | The lab standard for 50 mL–1 L flasks |

| Large | 29 mm | 29/42 | 29/32 | 1 L+ flasks, larger distillation setups |

| Larger | 34 mm | 34/45 | 34/35 | 2–3 L reaction vessels, heavy assemblies |

| Extra-Large | 45 mm | 45/50 | 45/40 | 5 L+ kettles, big stirrer shafts |

Note: Specific combinations may vary slightly by manufacturer and standard. The examples above represent the most typical pairings found in labs.

Spherical (Ball & Socket) Joints(Quick Reference Table)

Rule: Size code = Ball Diameter / Bore (Inner) Diameter

| Size Code | Ball Diameter (mm) | Bore ID (mm) | Typical Application |

|---|---|---|---|

| 18/9 | 18 | 9 | Small gas lines, rotovap inlet tubes. |

| 28/15 | 28 | 15 | Flexible connections in medium setups. |

| 35/20 | 35 | 20 | Rotovap Standard. Receiving flasks often use this. |

| 35/25 | 35 | 25 | Larger rotovaps or semi-industrial glass. |

Key Difference: Unlike taper joints, Ball & Socket joints have no friction lock. They rely entirely on metal clamps to hold together.

Maintenance & The Art of Clips

A well-made joint can last for years. However, poor maintenance can ruin it in a week.

Grease It Properly

If you have ever wondered how to grease glass joints correctly after fighting with a frozen joint, the key principle is simple: less is more.

- Apply a very thin ring of vacuum grease to the upper part of the male joint only.

- Insert the joint and rotate gently until the frosted area looks uniformly clear or slightly glossy.

- Avoid smearing grease along the entire length. Too much grease can creep into your reaction, attract dust, and actually make joints more likely to seize.

For readers who want a step-by-step routine, including cleaning and troubleshooting, you can dive deeper in our guide on how to use and maintain ground-glass joints.

Clips vs. Clamps: Don’t Mix Them Up

New chemists often treat clips and clamps as interchangeable. They are not.

For Standard Taper Joints → Use Plastic Keck Clips

- Function: Prevents joints from sliding apart and keeps the orientation fixed.

- Limitation: Not designed to carry heavy weight or support long, lever-arm assemblies.

For Spherical (Ball & Socket) Joints → Use Metal Pinch Clamps

- Function: Non-negotiable. Spherical joints have almost no self-locking friction.

- Without a metal clamp, a rotovap receiving flask or manifold arm can slip and drop under its own weight.

ChemNorth warning: Never rely on a plastic Keck clip to secure a ball joint—

it simply isn’t designed for that job.

If you are unsure which clip or clamp belongs on which joint, or you are choosing hardware for a new setup, you can explore the details in our guide on how to choose clamps and clips for laboratory glassware.

Buying Guide: Looking Beyond the Numbers

If you’re trying to decide which glass joint size you should use for a 250 mL or 500 mL flask, a simple rule works for most teaching and research labs:

- Glassware between 50 mL and 1 L is usually built around the 24 mm family (24/29 or 24/40).

- 29 mm and larger joints are reserved for big flasks, columns, and heavy-duty or high-vacuum assemblies.

In practice, for everyday organic work—reflux, simple distillation, basic vacuum work—a 24 mm joint is usually the best joint size for a 500 mL round-bottom flask. However, if you are building a tall vacuum distillation rig, running at high temperature, or hanging a lot of glass off one connection, stepping up to 29 mm or even 34 mm joints gives you more stability and strength.

Once the size is chosen, the overall quality of the joint matters more than another millimetre of diameter:

- Wall thickness at the joint – Better glassware has slightly thickened walls around the joint. This helps resist chipping and extends the service life of the piece.

- Grinding quality – You can feel this with your fingers. A good joint feels smooth and “silky”; a bad one feels scratchy like fine sandpaper, which makes leaks and frozen joints much more likely.

Finally, don’t forget the small parts that keep everything together:

- Buying spherical joints? Order the matching metal pinch clamps at the same time—these clamps are rarely included by default, but they are essential for safe, flexible connections.

- Buying standard taper joints? Make sure you have the right Keck clips on hand (sizes 14, 24, 29, etc.).

Conclusion

Understanding glassware joints isn’t just about buying parts with matching numbers. Instead, it is about knowing what those numbers mean, recognising the difference between US and European standards, and maintaining your equipment so it seals reliably.

Whether your lab runs on 24/40, 24/29, or a mixture of both, a bit of “joint literacy” goes a long way toward preventing leaks, breakages, and frustrated chemists.

If you are looking for high-quality, standardised glassware, ChemNorth works with manufacturers who follow strict international standards, focusing on precise dimensions, clean grinding, and durable joints that you can trust from one batch to the next.

(Bookmark this guide. The next time you’re staring at a drawer full of mismatched joints, you’ll have a roadmap instead of a guessing game.)g game.)

About the Author: Zoe.W

With over 20 years of experience in hand-blown glass manufacturing, Zoe.W is dedicated to bridging the gap between craftsmanship and laboratory application. Combining frontline lab feedback with deep industry knowledge, she specializes in solving complex equipment challenges for organic chemistry experiments.

Connect with Zoe: Email |